Inkjet Paper

Rapid development of inkjet printer technology realized photo-quality record and improved printing speed dramatically. With this development, the performance required for inkjet paper is changing. We are conducting the research and development to disseminate high-quality products and high technologies globally.

Long experience in inkjet technology

MPM started development of inkjet paper already in 1978. As a result of our research and development for more than 30 years, we have accumulated many technologies. We will continue to meet customer needs, combining our past experience and today's development. These technologies are also used in Germany, where our subsidiary is located.

Inkjet paper with higher quality

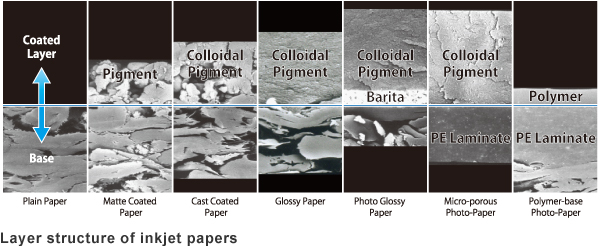

To be comparable to silver halide photography, inkjet technology needs specially designed inkjet paper. Inkjet paper is optimized for ink absorbency, color development water resistance, light resistance, gas resistance, and runnability on printers to provide excellent output.

Matte coated paper is coated with absorptive pigment that has a smaller particle size than dot size in order to provide better ink absorbency and print uniformity.

Glossy paper is made by a process called the "cast process ." Here, the coated layer is pressed onto the hot mirror surface while it is wet. Moisture in the coated layer evaporates from the backside, and the surface of the mirror surface is replicated on the surface of the paper. This type paper is used for glossy postcards, for example.

Proofing paper is used by printing professionals. Commercial printers are requested to show samples of the final product to their clients before they proceed to actual printing. Output used for this purpose is called the "Proof." Inkjet technology is widely used for this purpose today. For this application, paper must have an appearance quite similar to the paper used for the actual printing. In addition, the printed color must be very stable.

And today, inkjet paper is used even for artwork. Since the texture of paper is a part of the feature of artwork paper can create the aura that the designer seeks. In other words, we think the texture of paper is one of the important qualities.

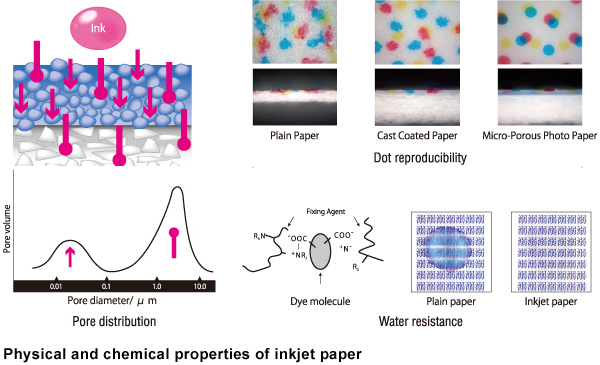

In order to develop such high-performance inkjet papers, we utilized various physical and chemical phenomena to achieve the required qualities. For example, nanocavity size, ink absorbency, ion affinity, and layer architecture are optimized to meet the required properties (Figure: Physical and chemical properties of inkjet paper).

Inkjet technology is still advancing today. High quality inkjet paper is essential for high quality output. We are developing inkjet paper with higher quality, not only for new printers but also for old printers.

Inkjet photopaper

Inkjet photopaper that makes up beautiful photo.

This may be the most familiar product of nanotechnology with us.

No.1 market share

You can find inkjet photopapers wrapped in colorful packages in all superstores. In fact, most of them are manufactured by MPM. Our annual production of inkjet photopaper exceeds 5,000,000,000 sheets (as the economy size). This is evidence of the number one domestic market share* for inkjet paper.

*:43.5%Source: Paper and Pulp White Paper2008,Yano Report

It's coming from porous ceramics structure

Innumerable picoliter droplets come out of the printer head. The ink absorbing layer of inkjet photopapers absorbs these droplets correctly and instantly. The surface area of the ink-absorbing layer of an A4 sheet is as large as a tennis court. The key is the porous ceramic structure comprising innumerable 20nm pores. Furthermore, this structure is transparent because it is made of inorganic superfine particles about 10 nm in size, which is much smaller than the wavelength of light. Therefore, the beautiful color of the ink can be reproduced.

Controlling inks as we like

-

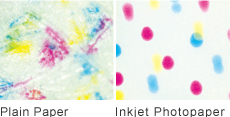

If an image printed on copy paper gets wet, it bleeds. Curiously, however, an image printed on inkjet photopaper does not bleed. An electronic change in the ink-absorbing layer plays a great role in giving a strong ionic bond between the ink and the porous ceramics. In addition, inkjet photopaper provides many functions for photos, such as color brightness, color strength, less color bleeding, and less color degradation.

Controlling light

A photo media printed on inkjet printer has a glass-like or pearl-like gloss. To obtain this delicate appearance a micron-size surface pattern and a thin layer less than 100 nm are utilized to control light interference.

Outstanding technical capability shown by many registered patents

We have more than 100 registered patents for inkjet photopaper to protect our products and technology. This is our history that we have continuous development since the dawn of inkjet technology.

To the future

A wide range of ink-absorbing layer technologies are thoroughly utilized not only in general-purpose inkjet products but also in our original brand Pictorico® series and Gekko ® series monochrome inkjet paper.

In addition, we will create new applications one after another beyond the traditional framework, such as printable media for video recording and in-mold decoration of plastic and printable electronics base material and the like.

Resin Coated Paper

Resin Coated(RC) Paper is both sides laminated with polyethylene and used for photographic paper.

We produce RC paper based on our long experience in photographic paper. This technology is also applied to inkjet photopaper to give high quality output comparable to silver halide photography.