Printing Paper

Paper is essential for our daily life.

Our products meet high quality demands through severe optimization of process and materials.

Eco-conscious production

Sustainable forest resource management is one of the most important policies of our company. Our products are made exclusively from planted resources. We are the first Japanese paper manufacturer certified by FSC, which is known as the most demanding certification program for eco-concious forest industry products. All production sites of our group are CoC certified by FSC.

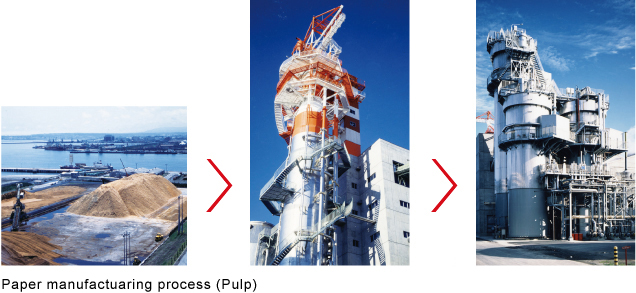

Papermaking process

Pulping is the first step in the papermaking process. In this step, wood chip is "digested" i.e. converted into slurry by a process called the "Kraft Process.“ The slurry is then bleached by the eco-conscious Elemental Chlorine Free (ECF) process. The bleached pulp is then converted into paper through several process steps. The major part of our product is further treated by pigments and chemicals to meet various required properties. We are continuously the working on development of innovative production processes.

Meeting market demands

We work hard to meet the daily changing demands of the market. Low density publishing paper, which makes books more portable, coated paper with superior brightness, and digital on-demand printing paper are a few examples of our newly developed product line.

Communication Paper

Thermal paper spreads across applications, not only as facsimile paper. ThermoRewrite® is derived from thermal paper technology. Communication paper is developing further by taking advantage of technology we cultivated.

Extending application of thermal paper

Along with the extension of its application, demand for thermal paper has been increasing. Besides its conventional application facsimiles, cash registers, food labels, and ATMs, thermal paper is today used in various applications such as tickets, logistic labels, and handheld terminal outputs where various additional features are required.

Based on our unique technologies, we created the AF (Anti-Fade) system, in which print image stability is drastically improved, and multicolor thermal system where different color appears when a different amount of heat is applied. Responding to various requests from the market, we also developed thermal paper with different functions such as heat resistance, light resistance, water resistance, and offset printability. We are making continuous efforts to meet increasing demand for even higher functionality.

ThermoRewrite® is eco-conscious

ThermoRewrite® is a recording material that can be rewritten more than 300 times. Thanks to this feature, ThermoRewrite® contributes to resource saving as well as waste reduction.

The material can be used in a wide range of applications, including cards, tickets, RFID (Radio Frequency IDentification), the factory automation field, and displays ThermoRewrite® products are available in a blue image color version and a black image color version at the moment.

Principle of ThermoRewrite®

Like conventional thermal printing paper, ThermoRewrite® also comprises Leuco dye and developer. With our newly developed developer, the reaction between these materials became controllable.

You can choose the colored state and the colorless state just by controlling the heating and cooling process. More in detail you can choose the colored state by heating the mixture at temperatures higher than the melting point (170℃-180℃) and then cooling it rapidly. On the other hand, you can choose the colorless state by gradual cooling (ca,100℃/sec) the paper after heating. The key to this discoloring process is rapid phase separation and crystallization realized by the optimally designed molecular structure. Actually, the ThermoRewrite® can be erased even at temperature lower the melting point (120℃-150℃) since another phase transition pathway from the colored state to the colorless state exists. This is explained as the relationship between time, temperature, and print density in the figure above.